Filter

Sorting

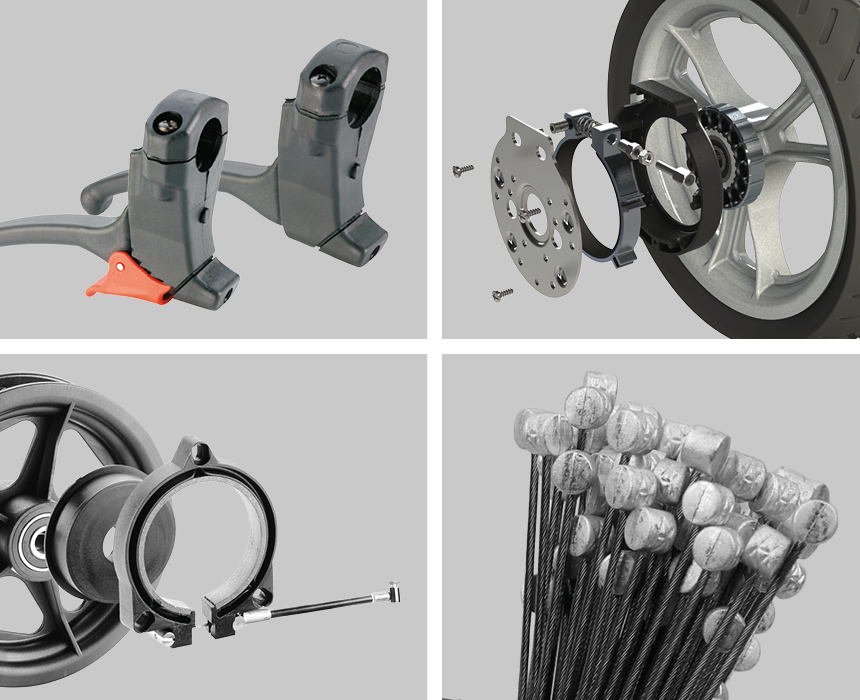

Bowden cable 1.100 mm, steel

Outer cable 5,8 mm, bulb 6 - 3,5 mm, bulb adjusting screw, ideal eg for rollators.

Item no. BZ-ROL

Bowden cable 1.500 mm, stainless steel

Outer cable 5.8 mm, barrel 7x6 mm, bulb 6 - 3.5 mm.

Item no. BZ-HB-U-VA7X7

Bowden cable 1.500 mm, steel

Outer cable 5.8 mm, barrel 7x6 mm, bulb 6 - 3.5 mm.

Item no. BZ-HB-U

Bowden cable 2.000 mm, steel

Outer cable 5,8 mm, barrel 5x6 mm, for release lever.

Item no. BZ-AH

Bowden cable 800 mm, stainless steel

Outer cable 5,8 mm, barrel 7x6 mm.

Item no. BZ-HB-800/670

Bowden cable switch

Incl. 3 adjusting screws, for 2 Bowden cables and barrel 6x7 mm.

Item no. BZW-E

Drum brake hub made of aluminium

Silver anodised, 36 spoke holes, ball bearing 12 mm, hub length 50 mm.

Item no. NA-TOP-B-12

Hand brake made of aluminium

One-hand multi-circuit brake, lockable, for 2 Bowden cables, tube clamp: 22 mm.

Item no. HB-F-EMB

Hand brake made of plastic

Lockable, self-locking, Bowden cable outlet 36°, tube clamp: 25 mm.

Item no. HB-F-RK36SR25

Hand brake made of plastic

Lockable, self-locking, Bowden cable outlet 80°, tube clamp: 22 mm.

Item no. HB-F-RK80SR22

Hand brake made of plastic

Manually lockable, Bowden cable outlet 36°, tube clamp: 22 mm.

Item no. HB-F-RK36MR22

Hand brake made of plastic

Lockable, self-locking, Bowden cable outlet 36°, tube clamp: 22 mm.

Item no. HB-F-RK36SR22

Hand brake made of plastic

Manually lockable, Bowden cable outlet 80°, tube clamp: 25 mm.

Item no. HB-F-RK80MR25

.jpg)